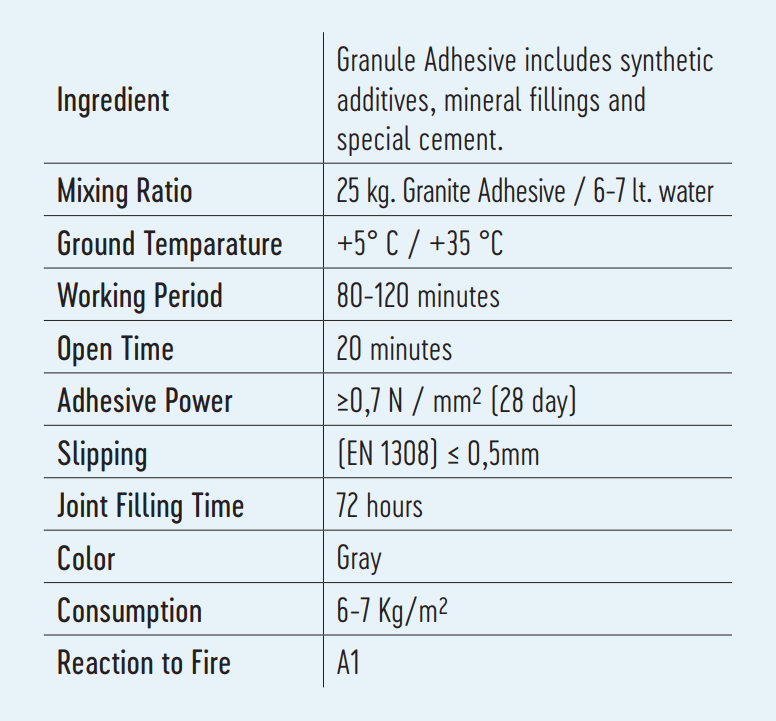

Plus Granit and Marble Adhesive cement-based granite, ceramics, tile and marble adhesive with regular hardening and high stability. It is a strong adhesive used for fixing natural granite, ceramics, tile and marble materials in various sizes and thickness on to the surface.

APPLICATION AREA

• Used for fixing wall and ground ceramic tiles on to the concrete surface, plaster, cement nish and wall surface areas. Has high bonding stability. Creates non-slip surface and easy to use.

APPLICATION INSTRUCTIONS:

PRELIMINARY PREPARATION

• Check beforehand the firmness, water absorption and solidity of the surface where the product will be applied on. Use Asvil Water Isolation additive to eliminate water absorption if the water absorption of the surface is high. Repair the defects and voids on the surface needing overhaul beforehand. Ensure that the surface to be covered is clean and free from dust, dirt, residues, grease and any other contamination.

MIXTURE AND APPLICATION

• Pour 6-7 liters of water into the mixture container and slowly add adhesive over the water until a homogenous and consistent paste is obtained. Use a low speed mixer for mixing. Using a high speed mixer may inhibit obtaining a consistent paste. Wait 5 minutes for maturation and mix the mortar again; the mortar is ready to use. Make dredging by applying mortar on to the surface by using ceramic dredge proper for a tile size. Make double-faced pasting for heavy covering materials (specically for Granite-CeramicsMarble) and external coating applications by applying a thin layer of mortar on rear side of the covering material. Such special application is needed because the Granite-ceramics is in the category of heavy ceramic group. And, the water absorption of Granite-ceramics is very low and it has high vitreous structure. Use a rubber tamper to apply the covering material onto the dredged mortar. The tools and equipments should be washed with plenty of water immediately after use. Never attempt to make bonding on the expired material and that should be cleaned from the surface. Hardened material in the container with completion of setting is unusable.

WARNINGS AND PRECAUTIONS

• Avoid application under temperature limits below +5°C and over +35°C.

• Ensure that the application surface is clean and free from dust, dirt, residues, grease and any other contamination.

• Mix the material by maximum 120 RPM mixer.

• Consume the prepared mortar within 2 hours of mixing.

• Do not absolutely make any inclusion (such as lime, sand, cement) other than water.

• Apply joint filler after 24 hours as from completion of bonding. During this time, do not step up on the applied surface and protect the surface from water.

• Protect the surface from external factors (wind, wet and sunlight) during the application.

• The shelf life is preserved in unopened package in proper storing medium.