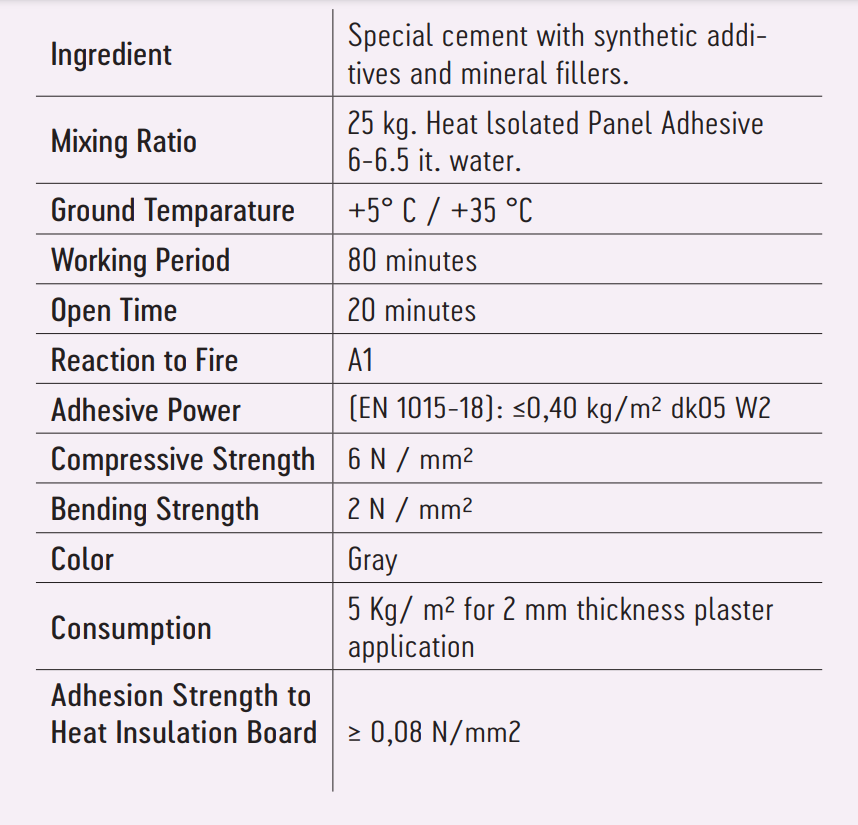

Heat lnsulation Board Plaster, simply prepared and applied, cement based final coat plaster mortar with high stability, strengthened with synthetic additives and powder polymers, used far final coat of plaster applied on polystrene boards (XPS-EPS).

APPLICATION AREAS

• It is used for the 1st and Last Layer and of the heat panel (XPS-EPS) plastering, which were applied on internal end external fronts. Undercoating painting application can be applied on, after making rosşa.

APPLICATION

• 25 kg. Heat lsolated Panel Plaster is mixed with 6-6.5 Lt. water and stirred and left for settlement approximately for 3-5 minutes and by mixing again for 1-2 minutes gets ready for using. it must not be applied on the frozen surfaces or the surfaces that was stayed under the sun for a long time.

SURFACE PREPARATION AND APPLICATION

• After purifying of the applied panels from dust vb. materials, 6.5 Lt.

• Water is added into 25 kg. heat isolated panel plaster plaster and mixed until it becomes paste thickness. İt is left for 3-5 minutes for settlement and gets ready to use. This paste thickness mortar is applied with gypsum plaster trowel on the heat isolated panel approximately for 2 mm. Thickness. Before drying the plaster net is embet to the first layer applied plaster by pressing trowel and left for drying. Connection places of the nets have to be one right after the other minimum 8 cm, maximum 1 O cm. After this procedure at least 24 hours must be waited for the second application.

• Smooth the surface with a steel trowel following application of the second coat of plaster (2 mm).

• As it is a Cement basis material, the hands needs to be protected.

• Gloves have to be used.

PACKAGINGAND STORAGE

• Shelf life is 10 months in 25 kg kraft bags stored in dry and cool place.